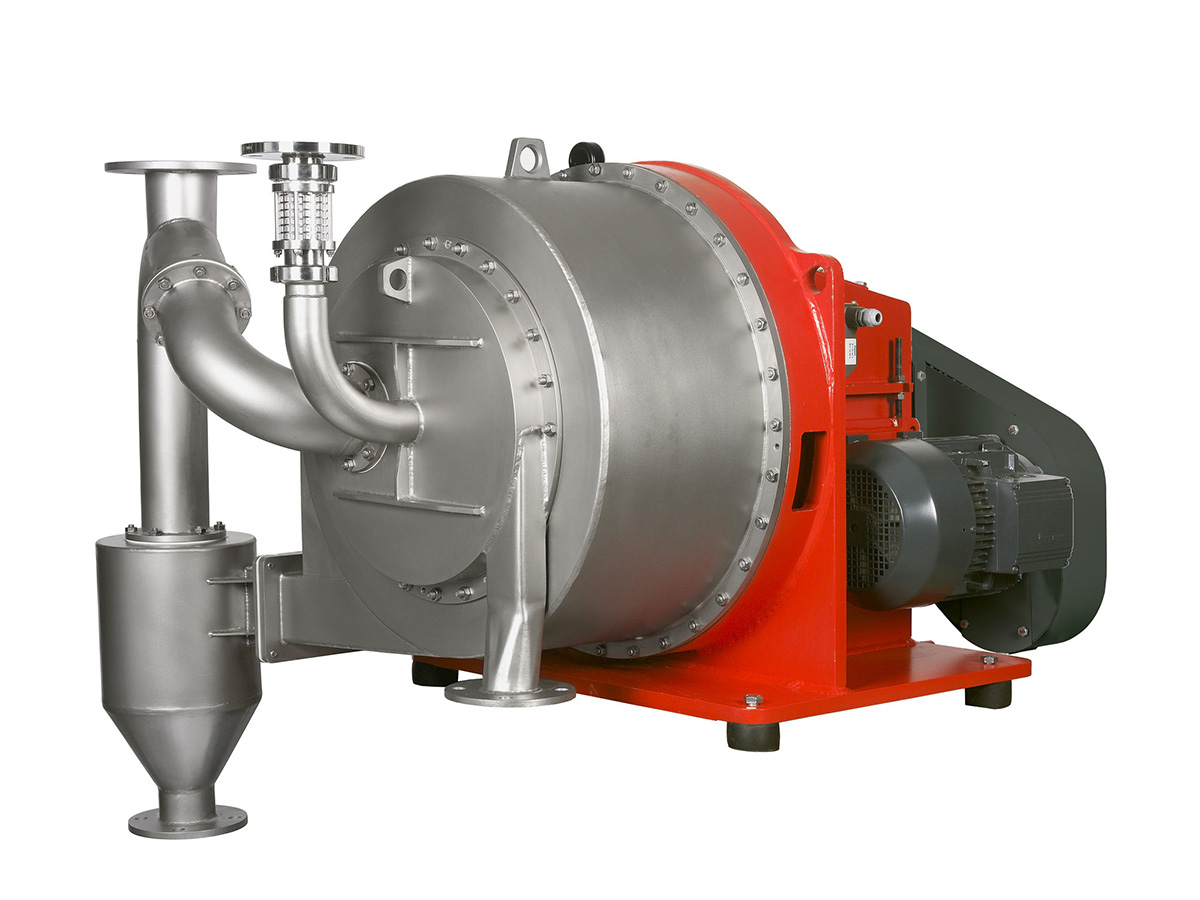

Centrífuga deslizante TURBOCASCADE

TURBOCASCADA centrífuga deslizante

Centrífuga para granulados

La centrífuga deslizante TURBOCASCADA es una unidad especial que se utiliza principalmente para la deshidratación de partículas de tipo granulado.

Las principales áreas de aplicación de esta máquina son los gránulos de polímero que se separan del agua que lleva o de una suspensión. A pesar del corto tiempo empleado por los productos en la centrífuga, se alcanzan niveles de humedad final de hasta 0.05%.

La TURBOCASCADA es una centrífuga robusta, potente y eficiente. La instalación y el mantenimiento son extraordinariamente sencillos.

Comportamiento operativo y características mecánicas

Durante la operación, las partículas sólidas se deslizan a través de la cesta de filtrado escalonada. La tensión sobre el granulado de polímero, así como la abrasión del producto, es muy baja. Esto se logra mediante un sistema especial de guíado de material y nuestros chapas Conidur® o rejillas OPTIMA.

La separación es intensiva y, mediante la separación puramente mecánica, se logra un nivel de humedad residual muy bajo. Normalmente, la centrífuga opera con un sistema de pre-desaguado ajustable para separar parte del agua antes de la centrifugación. La capacidad del TURBOCASCADA es considerablemente mejorada por esto. La centrífuga ocupa muy poco espacio, considerando su capacidad de separación.

Variantes de ajuste

Dependiendo de los requerimientos y las condiciones de operación, utilizamos como elementos de cribado las chapas perforadas Conidur® o las rejillas ranuradas, que debido a sus propiedades de autolimpieza no se colmatan con astillas o hilos del granulado. También fabricamos la TURBOCASCADA hermética al gas y al vapor. El aire en circulación primero se limpia de cualquier resto de agua en un separador ciclónico y luego se devuelve a la carcasa. Gracias a este principio de diseño, las pérdidas de calor en la centrífuga son muy leves. El sólido deshidratado se puede descargar en cualquier posición, vertical u horizontalmente, según lo requiera el cliente.

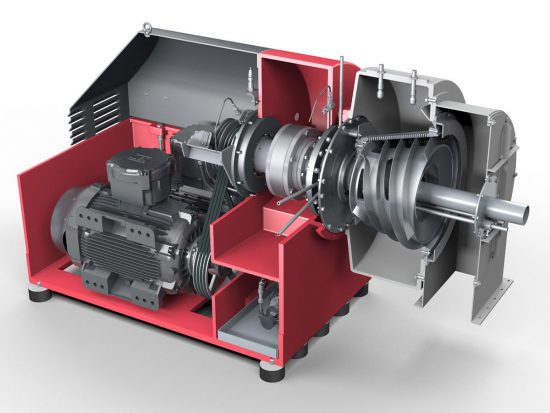

Drives for centrifuges

The solution to a separation task depends very decisively on the centrifuge drive. The centrifugal force required for solid-liquid separation is determined by the bowl or screen speed. To achieve the right speed for optimum separating results, it is frequently necessary to keep the speeds variable. The drive control needed for this is designed by our specialists specifically to fit your application.

Furthermore, on screen worm centrifuges and in decanters the speed differential between the solid-conveying worm and the bowl is decisive. It determines the time which the solid spends in the centrifuge and so the quality of the drying. The correct speed differential for your separation task is determined by the correct choice of gear unit. The speed differential here may be constant, but may also be variable. In the latter case the back-drive, where the otherwise fixed gear input shaft is also driven, is used. If the worm speed is required to be kept completely independent of the drum speed, hydraulic drives (viscotherms) or two-stage gear units with an upstream differential planetary stage are used.

To guarantee the operational reliability of your centrifuge, the drive system is continuously monitored. Excessive speeds, overcurrent and slip are identified and reported to the machine control system and there processed.

Only a drive system specially designed for your separating task will give optimum separating results.

Explosion protection / inertising

Explosion protection/inertising

Inertisation of our machines and systems may be necessary for various reasons. In many industrial processes it is necessary for safety reasons to reliably prevent the build-up of an explosive atmosphere through dust or gases (ATEX).

It may also be necessary to seal and overlay the product spaces with inert gas, e.g. nitrogen (N2) or carbon dioxide (CO2), to prevent oxidation and maintain product quality.

Use SIEBTECHNIK specialialists’ many decades of experience in all areas of industry to help seal and inertise the process spaces in your centrifuges.

We will be pleased to work with our customers to draw up an inertising concept for the integration of our machines into existing or scheduled plant systems.

Hygienic Design / CIP

The name SIEBTECHNIK is inseparably associated with dewatering tasks to meet the most stringent hygiene requirements. The separation of batter from frying oil at temperatures of approx. 200°C with the SHORTBOWL decanter centrifuge, the centrifuging of lactose crystals with the SHORTBOWL decanter centrifuge and the CONTURBEX screen worm centrifuge for the manufacture of baby food or the manufacture of extremely pure inorganic salts with our CONTURBEX and pusher centrifuges are some examples. Design features for this are the technical separation of the drive and processing sections of the centrifuge and highly developed sealing systems that are easy to clean by CIP.

For the optimisation of centrifuges in the hygiene sector and/or in areas where e.g. cross-contamination has to be prevented by CIP we use riboflavin tests to examine and optimise cleaning results.

Our self-developed and USDA-certified CIP nozzles, self-developed hygienic screw connections, special hygiene surfaces or our highly developed USDA-conformant sealing technology make many dewatering tasks possible only with our centriguges.

Service

Our reliable service enables optimum operation of your machines and systems. We offer energy optimisation, machine monitoring, an on-site maintenance and & repair service, OEM spare parts, damage cause analysis, maintenance & repair kits, stock inventory analysis, machine history management, personal technical consultation, training & workshops, 24 hr service, retrofitting & upgrades and used & loan machines.

Ask us, we’re there for you.

System solutions

SIEBTECHNIK TEMA has consistently developed itself into one of the world’s most innovative manufacturer of continuous centrifuges and suppliers of system solutions in the field of mechanical and thermal solid-liquid separation since the early 1940s. SIEBTECHNIK/TEMA is your reliable partner for customer-focused, custom-built machines and system solutions.

SIEBTECHNIK TEMA centrifuge and drier systems offer you the latest technology, customer- and product-specific special fittings and individual consultation at the pre-sales stage and reliable support in the after-sales process. For mechanical liquid separation continuously operating centrifuges are often the technically and economically best solution. They separate large volumes in closed housings with little space requirement and low energy and time costs. Also drying on the fluidised bed with fluidised bed driers and coolers has established itself in numerous branches of industry and applications.

Ventajas

- Operación continua

- Operación segura del producto

- Protección del producto gracias al diseño estanco al gas

- Intensa acción de separación

- Bajo consumo de energía específica

- Pequeño espacio requerido

- Baja pérdida de calor gracias al sistema de circulación de aire

- Calefacción y aislamiento opcionales

- Alta disponibilidad de la máquina

- Mantenimiento mínimo

- Larga vida útil